Our Fish

Sustainable, Traceable, Wild-Caught Alaskan Seafood

Our Mission

Sea to Shore Seafood Co. is about more than just selling fish. For us, it’s about creating a business model that allows us to follow our passion: to catch fish and bring beautiful, wild-caught Alaskan seafood to market –while doing so in a way that is sustainable, traceable, limits waste, and produces an unrivaled, quality product.

Impeccable Quality

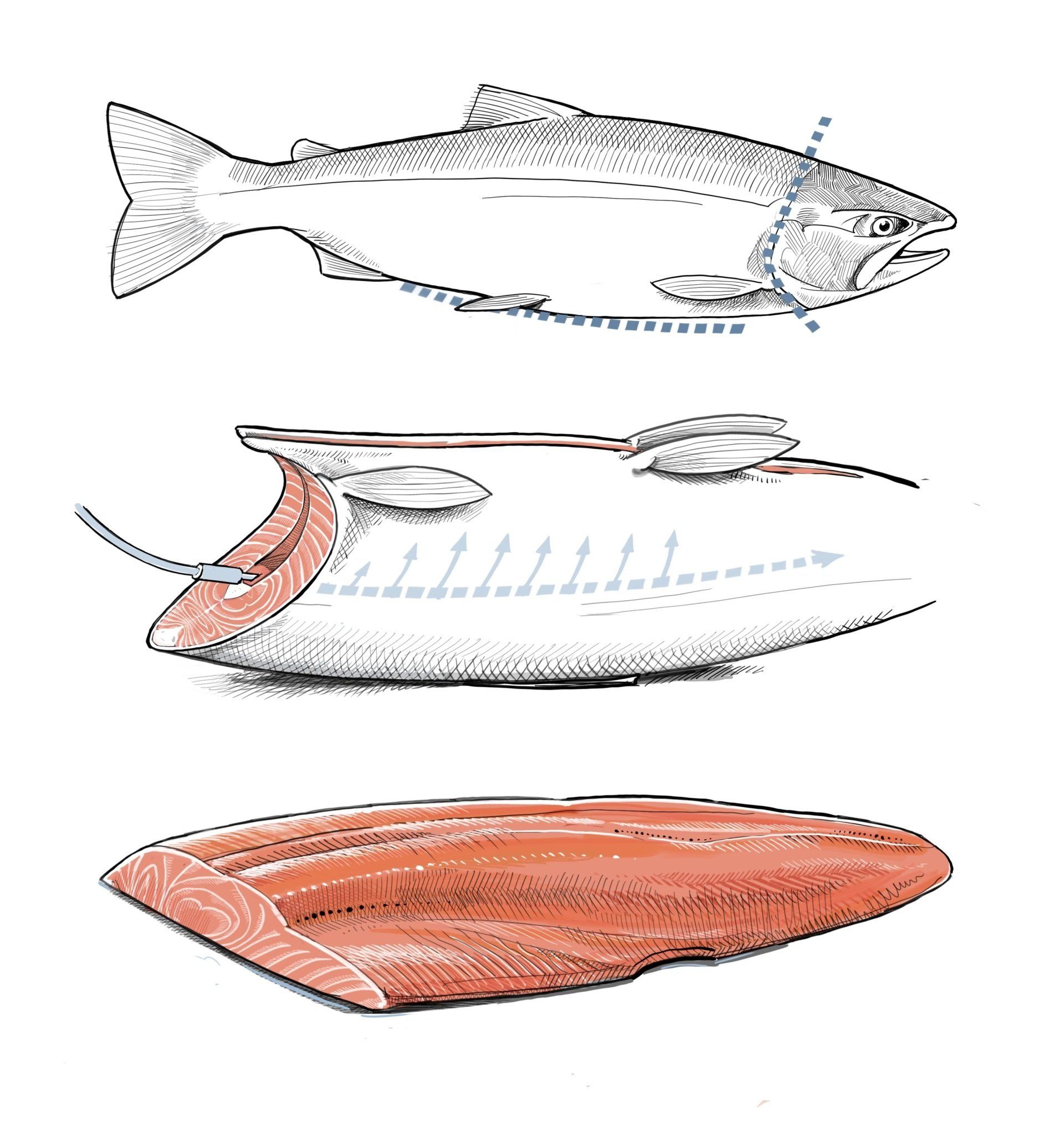

At Sea to Shore, we pride ourselves in taking the extra steps to ensure that every piece of seafood we source or personally harvest and deliver is of the highest quality. So, how do we uphold these quality requirements? The first step is educating ourselves and our fleet-mates on proper handling practices and with state-of-the-art processing techniques. The flesh of a fish is so fragile that just a few degrees difference in storage temperature, or rough handling, can affect the taste and texture of a fillet. At Sea to Shore, every piece of seafood that is sold has been both bled (where applicable) and processed at sea*. The removal of excess blood and internal organs is a crucial step in optimizing quality and this results in a fresher tasting and longer lasting product. Excess blood is the main culprit for spoilage, mushy texture, and that repugnant “fishy taste” we all try to avoid. After processing, each piece of seafood is then frozen onboard or immediately put into slushed ice until delivery. Upon delivery, each batch of fish is offloaded and kept separate awaiting further processing. This offers a fully traceable product, back to the fisherman who harvested it. This is also an important part of quality control so that we can monitor these deliveries and amend any quality concerns.

On our vessel, the F/V Eric, we take our processing of salmon a step further. As soon as a fish comes onboard, we swiftly and respectfully dispatch the fish in the most humane way we can. Our technique prevents the release of stress induced lactic acid that would otherwise have a negative effect on the texture of a fillet. An incision is then made in the salmon’s gill, followed by placing it into a tank of circulating sea water, allowing as much blood as possible to naturally drain. Our next process is what really elevates our salmon, making it a step above others on the market - pressure bleeding. Pressure bleeding is a time-consuming technique essential for achieving this rare, top-of-the-line product. A surgical pipette providing a low-pressure stream of sea water is inserted into the dorsal artery - the main artery of a salmon. For one to two minutes, this water gently pushes all the remaining blood from the salmon’s circulatory system. (As we stated above, blood is the number one cause of spoilage, so pressure bleeding significantly extends the shelf life for fresh salmon. This is very beneficial for retail and restaurants alike as it cuts down on wasted product.) After being thoroughly cleaned and inspected, it is then placed into an insulated tote of slushed ice. The salmon is held here until arriving shoreside, where it is filleted and blast-frozen or shipped out fresh to our loyal, eagerly awaiting customers. We take immense pride in this time consuming and labor-intensive process, but it is the only way we can guarantee that each salmon fillet is of the highest quality possible, from fish that have been handled with the most respect possible. Don’t take our word for it though,

read what our customers have to say!

*As of now, products that are not initially processed onboard the vessel is our Dungeness Crab Clusters and Side Stripe Shrimp. They are delivered live to the processor.